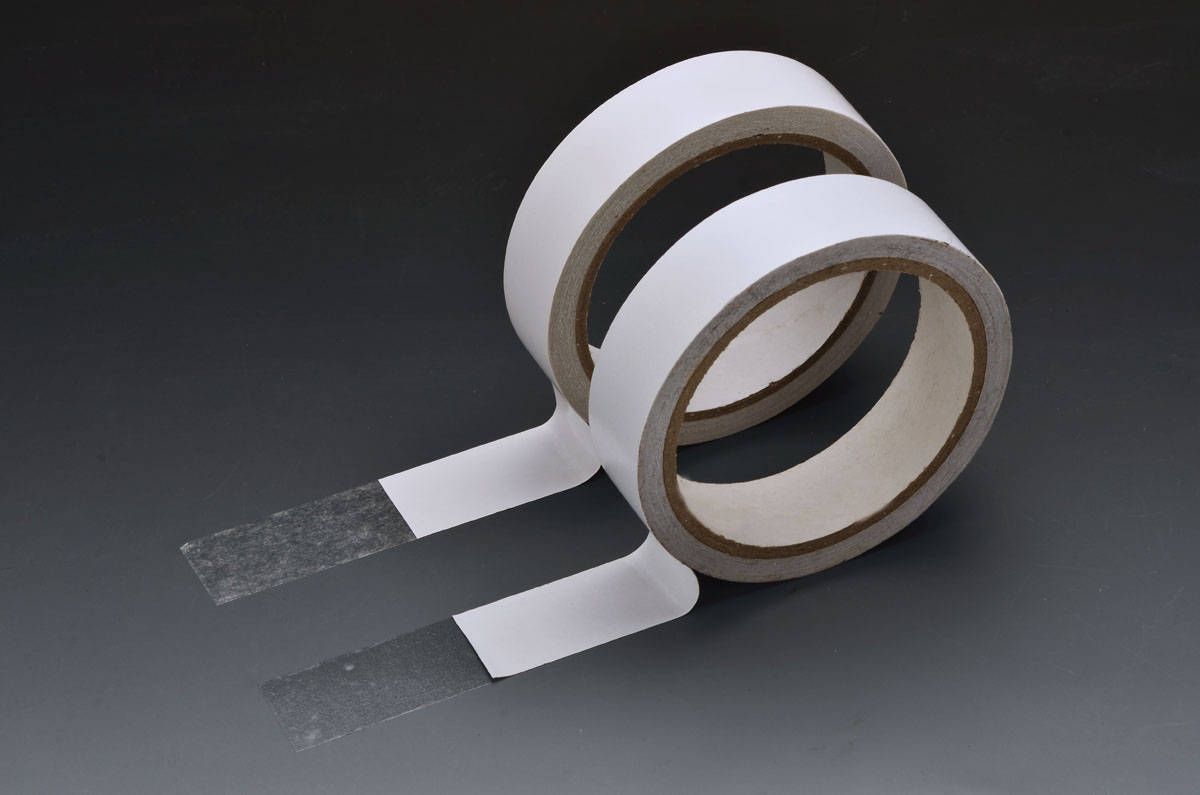

Tissue Double Coated Adhesive Tape

DS1-ABW49100

Double Side Tape, Mounting tape, double coated adhesive tape, double coated adhesive tape,pressure sensitive adhesive double coated tape, 3M 9086

Description

During the lifetime of vehicle, boat or yacht static and dynamic stresses act upon the constructive bond between the object and the subject part. Celadon® Double Coated Tape creates a powerful bond even between materials with different surface characteristics, such as low surface energy, EVA, EPDM form, plastic parts connection.

Celadon Tissue Double Coated Adhesive Tape is 0.15mm double coated with solvent base poly-acrylic pressure sensitive adhesive and backing with 110gsm silicon coated release paper liner.

Application Techniques

The bond strength of Celadon depends on the area of adhesive to surface contact developed during application and substrate type and surface conditions. For maximum bond strength, the surfaces should be thoroughly cleaned with a 50:50 mixture of isopropyl alcohol and water. Ideal tape application is accomplished when the temperature is between 21°C-38°C (70°F-100°F) and the bond is allowed to dwell 72 hours. Initial tape application to surfaces at temperatures below 10°C (50°F) is not recommended. Moderate heat lamination (65°C at 72.5 psi for 1-5 minutes) is recommended on rough surfaces.

STORAGE and SHELF LIFE

The shelf life of Celadon Adhesive Transfer Tape ATR2165 is 6 months from the date of manufacture

when stored in the original packaging materials and stored at 21°C (70°F) and 50% relative humidity.

Features

- High initial tack and adhesion bonding low surface energy material

- Excellent cold shock performance

- High humidity and UV resistance

Specification

Thickness | Tissue + Adhesive = 0.15mm +/- 0.01mm |

Adhesion | 2.5kgs/in (ASTM D3654); 25um PET as reinforce substrate |

Shear strength | 25℃*1kg*24hrs & 80℃*0.5kg*24hrs |

Substrate | 30um / Tissue / white |

Liner | 110gsm / 2PE paper |

Service Temp. | -10 deg-C to 80 deg-C |

Recommended Applications

- Foam Gaskets and General Foam Bonding.

- Bonding of Textured and Rough Surfaces.

- Fabric and Textile Bonding Including Floorcovering Lamination.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More