Unleashing the Artistic Potential: Exploring the Vibrant World of Vinyl for Sandblasting

Step into the vibrant world of vinyl for sandblasting and unleash your artistic potential like never before. With its versatility and precision, vinyl has revolutionized the art of sandblasting, allowing artists and craftsmen to create intricate designs and stunning visual effects with ease.

Whether you're a professional artist or a DIY enthusiast, vinyl for sandblasting opens up a whole new realm of possibilities. From customizing glassware and mirrors to adding unique patterns and textures to metal, vinyl provides the perfect canvas for your creativity to flourish.

With its adhesive backing and durability, vinyl stencils offer precise and clean lines, ensuring your designs are flawlessly transferred onto the surface. From simple shapes to intricate patterns, the possibilities are endless. Plus, the pressure from the sandblasting process ensures the design is etched deep into the material, creating a lasting impression that will withstand the test of time.

So, why limit your artistic vision? Embrace the vibrant world of vinyl for sandblasting and unlock limitless possibilities to elevate your craft to new heights. Let your imagination run wild and watch as your creations come to life with every delicate blast of sand.

Keywords: vinyl for sandblasting, artistic potential, versatile, precision, stencil, creative, sandblasting process, lasting impression.

Vinyl sandblasting is a unique and captivating art form that has gained immense popularity in recent years. At its core, the process involves using vinyl stencils to create intricate designs and patterns on various surfaces through the power of sand-blasting. The technique is simple yet effective, allowing artists and craftsmen to unleash their creativity in ways that were previously unimaginable.

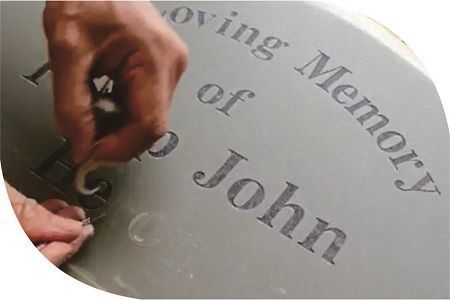

The process of vinyl sandblasting begins with the creation of a vinyl stencil. These stencils are precision-cut using specialized cutting machines or even by hand, depending on the complexity of the design. The vinyl material is carefully selected for its durability and adhesive properties, ensuring a secure bond with the surface being etched. Once the stencil is in place, the sandblasting process commences, with a high-powered stream of sand or other abrasive media being directed at the exposed areas of the surface.

The force of the sandblasting process etches the design into the material, creating a permanent and visually striking impression. The depth and texture of the etching can be adjusted by varying the pressure, duration, and angle of the sandblasting, allowing artists to achieve a wide range of effects, from delicate and intricate patterns to bold and textured designs. The versatility of this technique enables it to be applied to a diverse range of materials, including glass, metal, stone, and even wood, making it a truly versatile and captivating art form.

One of the primary advantages of using vinyl for sandblasting is its exceptional versatility. Vinyl stencils offer a level of precision and control that is unmatched by other materials, allowing artists to create intricate and detailed designs with ease. The adhesive backing of the vinyl ensures a secure and seamless bond with the surface being etched, preventing any unwanted bleeding or blurring of the design during the sandblasting process.

Another significant benefit of vinyl for sandblasting is its durability. The material is designed to withstand the intense pressure and abrasion of the sandblasting process, ensuring that the stencil maintains its integrity and delivers consistent, high-quality results. This durability also translates to the longevity of the final product, as the etched designs are deeply embedded into the surface and are resistant to wear and tear over time.

Furthermore, vinyl for sandblasting offers a wide range of color options, enabling artists to incorporate vibrant hues and striking contrasts into their designs. This versatility allows for the creation of truly unique and eye-catching pieces that stand out from the crowd. Whether you're looking to create custom glassware, personalized metal signs, or intricate patterns on stone, vinyl stencils provide the perfect canvas for your artistic vision.

When it comes to vinyl for sandblasting, there are several different types to choose from, each with its own unique characteristics and applications. One of the most common types is adhesive-backed vinyl, which features a strong adhesive layer that allows the stencil to adhere securely to the surface being etched. This type of vinyl is ideal for a wide range of materials, including glass, metal, and stone.

Another popular option is removable vinyl, which is designed to be easily peeled off the surface after the sandblasting process is complete. This type of vinyl is particularly useful for creating temporary or reusable stencils, allowing artists to experiment with different designs and patterns without the need to create a new stencil for each project.

For more intricate and detailed designs, artists may opt for pre-cut vinyl stencils, which are precision-cut using specialized cutting machines. These stencils often feature complex patterns and shapes, making them ideal for creating detailed and visually striking designs. Alternatively, some artists prefer to create their own custom vinyl stencils using cutting machines or even by hand, allowing for a greater level of creative control and personalization.

Engaging in the art of vinyl sandblasting requires a specific set of tools and equipment to ensure the process is carried out efficiently and effectively. At the core of this setup is the sandblasting cabinet, a specialized enclosure that houses the sandblasting equipment and protects the user from the abrasive media used in the process.

Within the sandblasting cabinet, the key components include the air compressor, which provides the necessary air pressure to propel the sand or other abrasive media, and the sandblasting gun, which directs the stream of abrasive material onto the surface being etched. The choice of abrasive media, such as fine-grained sand, glass beads, or aluminum oxide, can have a significant impact on the final result, as different materials can produce varying levels of texture and depth in the etched design.

In addition to the core sandblasting equipment, artists and craftsmen will also need a range of tools to prepare the surfaces and apply the vinyl stencils. This may include cutting mats, utility knives, and precision cutting tools for creating the stencils, as well as cleaning supplies and masking materials to ensure a clean and seamless application of the vinyl. By assembling the right tools and equipment, artists can unlock the full potential of vinyl sandblasting and bring their creative visions to life with unparalleled precision and control.

Embarking on a vinyl sandblasting project requires a methodical approach to ensure the best possible results. Let's dive into the step-by-step process that will guide you through the journey of unleashing your artistic potential.

- Design and Preparation: Begin by creating or selecting the design you wish to etch onto your chosen surface. This can be a simple geometric pattern, a complex illustration, or even a personalized monogram. Once you have the design, use a cutting machine or manual cutting tools to precisely cut the vinyl stencil.

- Surface Preparation: Thoroughly clean and degrease the surface you'll be working on, whether it's glass, metal, or any other material. This step is crucial to ensure the vinyl stencil adheres securely and the sandblasting process delivers a flawless result

- Stencil Application: Carefully align and apply the vinyl stencil to the prepared surface, smoothing out any air bubbles or wrinkles to create a seamless bond. Make sure the edges of the stencil are firmly adhered to prevent any unwanted bleed-through during the sandblasting process.

The world of vinyl sandblasting is a vast and exciting canvas for artistic expression, offering endless possibilities for creative exploration. From the simplest of geometric shapes to intricate, detailed designs, the versatility of this medium allows artists to push the boundaries of their creativity.

One captivating avenue to explore is the incorporation of text and typography into your vinyl sandblasting designs. Whether it's a bold, eye-catching statement, a delicate script, or a playful monogram, the precise etching of letters and words can create a stunning visual impact. Imagine personalizing glassware, mirrors, or even metal signs with your own unique typographic designs, adding a touch of personalization and flair to your creations.

Another compelling direction for vinyl sandblasting is the exploration of nature-inspired motifs. From delicate floral patterns to intricate wildlife silhouettes, the natural world offers a wealth of inspiration for captivating designs. By translating these organic forms into vinyl stencils, artists can breathe life into their creations, transforming ordinary surfaces into enchanting works of art.

Embarking on a vinyl sandblasting project can be an exciting and rewarding journey, but it's important to keep a few key tips in mind to ensure your success. One of the most crucial factors is the quality and preparation of the vinyl stencil. Take the time to carefully design and cut your stencil, ensuring clean, precise edges and a secure adhesion to the surface. This attention to detail will pay dividends in the final result, as it will prevent any unwanted bleeding or blurring of the design.

Another essential tip is to meticulously prepare the surface before applying the vinyl stencil. Thorough cleaning and degreasing are essential to creating a smooth, uniform surface that will allow the stencil to adhere properly. This step not only ensures the longevity of your design but also helps to prevent any imperfections or inconsistencies in the final etched result.

Finally, mastering the art of sandblasting itself is crucial to achieving the desired outcome. Experiment with different abrasive media, pressure settings, and blasting angles to find the perfect balance that brings your vinyl design to life. Pay close attention to the depth and texture of the etching, adjusting your technique as needed to capture the essence of your artistic vision.

While vinyl sandblasting has emerged as a highly versatile and captivating art form, it is not the only technique available for creating intricate designs and patterns on various surfaces. It's important to understand the unique advantages and limitations of vinyl sandblasting in comparison to other popular methods, allowing you to make an informed decision on the best approach for your creative projects.

One alternative to vinyl sandblasting is the use of traditional stencils, which can be made from a variety of materials, such as paper, plastic, or metal. These stencils offer a more budget-friendly option, but they may lack the precision and durability of vinyl. Additionally, the sandblasting process can be more challenging with traditional stencils, as the abrasive media can potentially seep under the edges, resulting in less defined and consistent designs.

Another technique to consider is laser etching, which uses a high-powered laser to precisely etch designs into various materials. While laser etching can produce remarkably detailed and intricate designs, it is often a more expensive and specialized process, requiring specialized equipment and expertise. In contrast, vinyl sandblasting offers a more accessible and versatile approach, allowing artists and craftsmen to create stunning results with a relatively simple setup and a lower barrier to entry.

As you've discovered throughout this exploration, the world of vinyl sandblasting is a vibrant and captivating realm that offers endless possibilities for artistic expression. By harnessing the power of this versatile medium, you can unlock new levels of creativity and elevate your craft to new heights.

Whether you're a seasoned artist, a budding craftsman, or simply someone with a passion for unique and personalized creations, vinyl sandblasting provides the perfect canvas for your imagination to flourish. From customizing glassware and mirrors to adding one-of-a-kind patterns and textures to metal, stone, and wood, the possibilities are truly limitless.

As you delve deeper into the art of vinyl sandblasting, embrace the journey of experimentation and discovery. Explore different design ideas, experiment with various vinyl types and abrasive media, and constantly challenge yourself to push the boundaries of what's possible. With each successful project, you'll not only hone your skills but also uncover new avenues for creative expression, ultimately transforming ordinary surfaces into extraordinary works of art.

So, what are you waiting for? Unleash your artistic potential and dive into the vibrant world of vinyl sandblasting. Let your imagination soar, and watch as your creations come to life, leaving a lasting impression that will captivate and inspire all who behold them.

- Related Products

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More