Semiconductor CMP Mounting Solution

Semiconductors are an essential component in modern electronics and play a crucial role in the functioning of a wide range of devices, from smartphones and computers to automobiles and medical equipment. The fabrication of semiconductors involves a series of complex processes, including the chemical mechanical planarization (CMP) process.

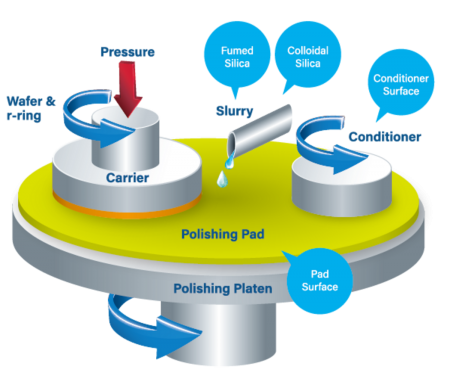

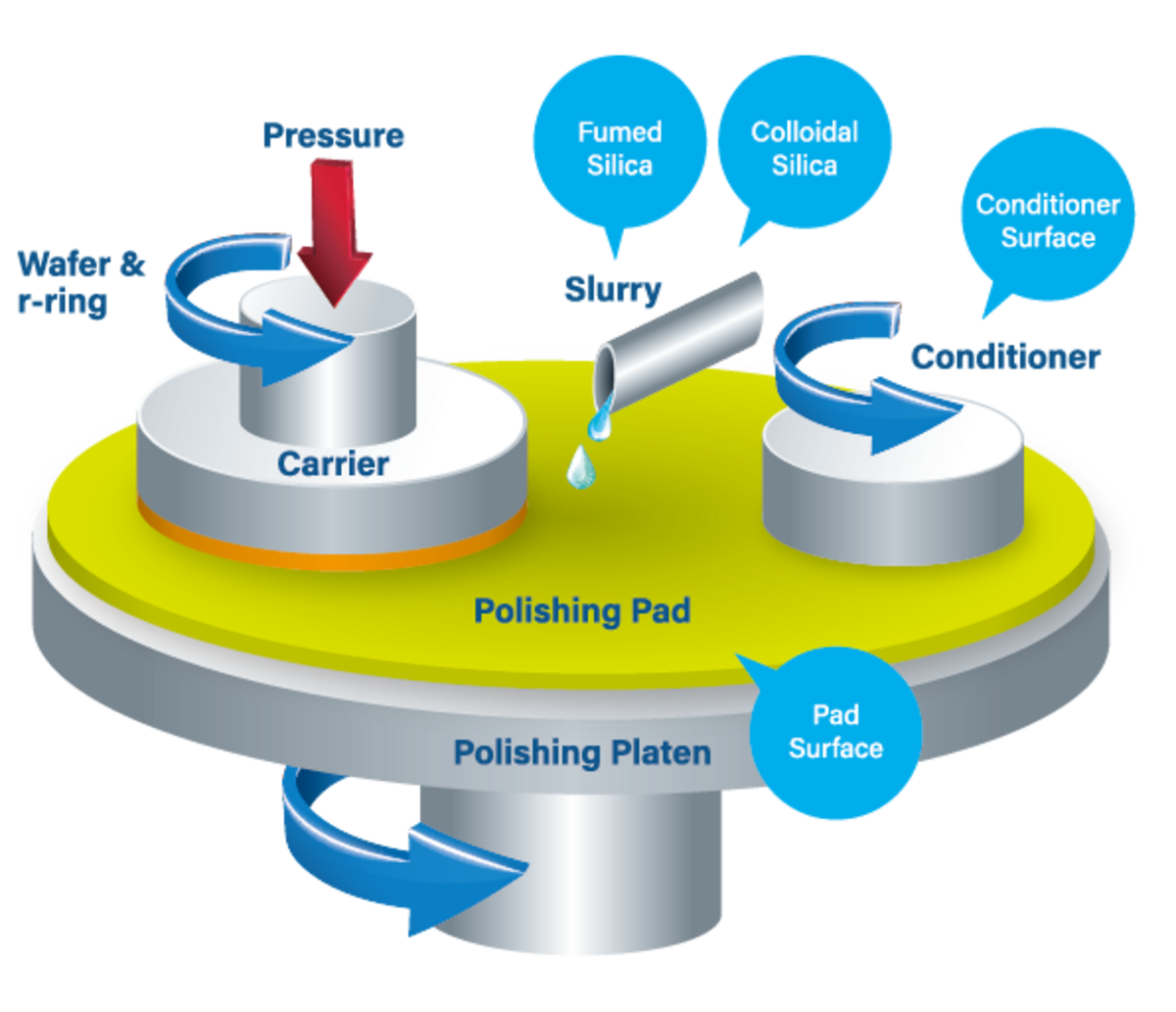

CMP is a process used in semiconductor manufacturing to produce a flat, uniform surface on a wafer. The process involves the use of a rotating pad and a slurry, which is a mixture of chemicals and abrasive particles. The wafer is placed on the pad and then subjected to pressure and movement, which removes material and produces a smooth, uniform surface.

One of the main advantages of the CMP process is its ability to produce a highly uniform surface, which is essential for the functioning of many semiconductor devices. The process is also highly efficient, allowing for the production of large numbers of wafers in a short amount of time.

Wafer bonding is an essential step in the CMP process. It involves the application of a thin layer of adhesive to the wafer, which holds the wafer in place on the rotating pad during the CMP process. Wafer bonding is performed on a specialized machine, which ensures that the adhesive is applied evenly and consistently to the wafer.

In conclusion, the CMP process is a critical step in the fabrication of semiconductors, providing a fast and efficient method for producing a uniform surface on a wafer. Wafer bonding is an essential component of the CMP process, providing the necessary stability to the wafer during the removal of material. The combination of these two technologies provides a powerful solution for the production of high-quality semiconductors.

- Related Products

PET Tape

We engineered Celadon Polyester Tape as a pressure-sensitive adhesive that grabs on contact and offers high heat resistance, reducing failure due to softening, oozing and adhesive transfer. This high-temperature tape is also designed with a thin polyester backing that resists With a 50um polyester backing and 40um adhesive, this tape features sharp, clean paint lines and provides excellent thermal, abrasion and chemical resistance while maintaining flexibility. In addition, Celadon Polyester Tape removes without leaving behind adhesive residue, for a clean finish.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More