Monomeric, Polymeric vinyl which one better?

Monomers are molecules that contain only carbon and hydrogen atoms. Polymers are made up of many monomers linked together. Calendering is a process where polymer films are stretched and heated to make them thinner and stronger. The most common types of calendered films are monomeric and polymeric. Monomeric films are usually used for packaging applications because they are strong and flexible. Polymeric films are often used for printing on paper products.

The Calendering Process

In order to create a calendered film, we first need to melt PVC resin, plasticizers and colorants together. Once melted, we pass the PVC through a series of rollers which flatten out the material and smooth out any imperfections. After passing through the rollers, the PVC is winded onto a spool.

About Plasticizer

The most common type of plasticizer used in vinyl flooring is phthalate esters. Phthalates are chemicals that soften plastics so they can be molded easily. Vinyl flooring contains a lot of phthalates because they make the vinyl flexible enough to mold. But these chemicals aren’t good for people. They can cause health issues like reproductive problems, hormone disruption, and cancer. That’s why we use only high quality REACH certificated plasticizers that don’t contain any harmful chemicals.

What do Monomeric and Polymeric mean?

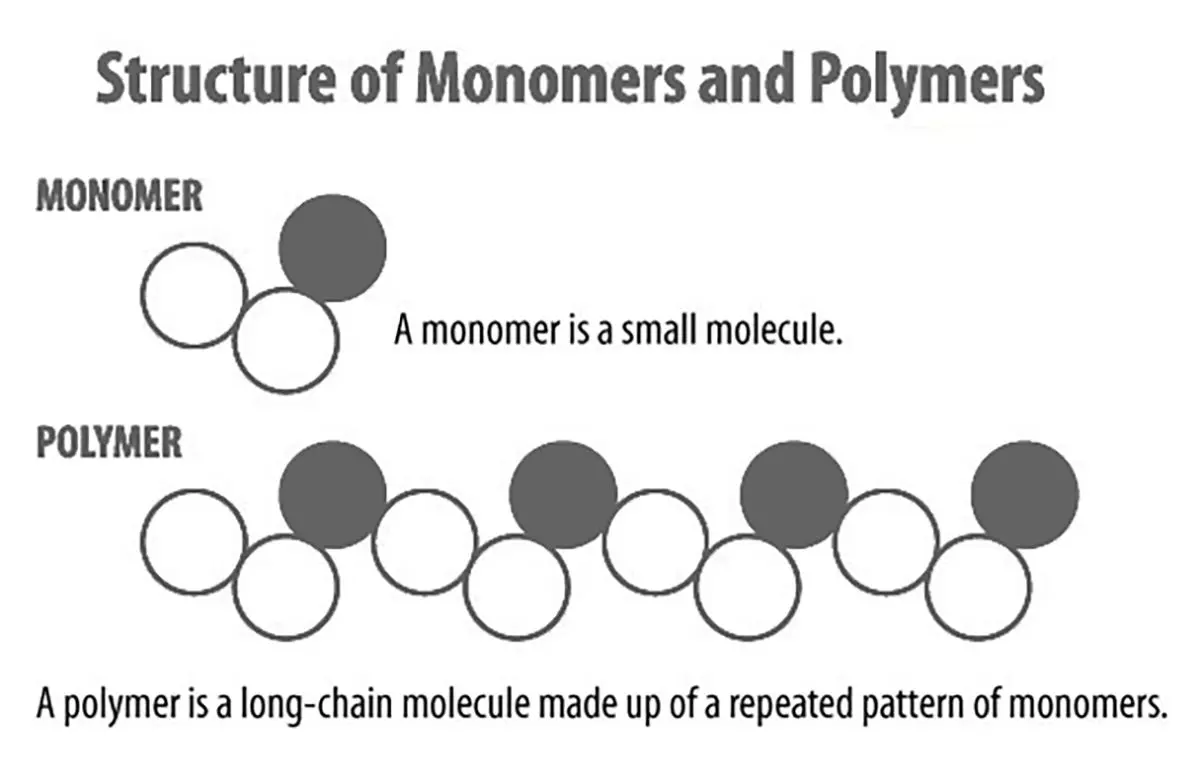

Mono- and polymers are both chemical compounds that consist of long chains of atoms. The difference between mono- and polymers is how these chains are connected together. In monomers, each chain is attached to only one other chain. This makes monomers very small molecules. In polymers, on the other hand, there are multiple connections between chains. These connections make polymers much larger than monomers.

Polymeric Films

Polymeric films are made of long-chain plasticizers. Longer chain molecules bond together much better than short ones, so polymers are much stronger than monomers. They also have a higher glass transition temperature, which makes them more resistant to heat and cold. Polymer films are typically thicker than monomeric films, ranging from 100–400 microns. This allows them to withstand harsh environments like snow, rain, wind, and salt spray. Polymers also have a longer-lasting outdoor durability than monomers.

Polymeric PVC film has a better outdoor durability

Monomeric Films

Monomeric films are made of short-chain plasticizers. These short chains do not bind into the film very well. Overall, the short-chain plasticizers tend to migrate out of the film, making it brittle. In addition, monomeric film varies in thickness. It can be between 80 400 micron thick and has a tendency to shrink. especially the softer and flexible film. Therefore, these films are best for indoor flat applications and have a 3 – 5 year outdoor durability. Lastly, monomeric films have short-term outdoor durability that varies by manufacturer, making them more economical.

Monomeric PVC film is suitable for indoor or short-term outdoor application

Polymeric Film | Monomeric Films |

|

|

- Related Products

Glossy Opaque Color Vinyl

Celadon Opaque Self-adhesive Calendaring Vinyl Film is a premium quality calendar film designed for use in signage markets where high-quality film finish and cost-effective full-color wrapping is required. It has a glossy Opaque color outlook that allows every project goes smoothly when you use Celadon Opaque Vinyl. This amazing vinyl lies flat on your cutting machine, no tunneling or bubbling. Cut your design, weed with ease, and apply with awe. Even your most intricate designs effortlessly separate from the carrier sheet for a perfect application. Water-resistant and UV-resistant, lasts up to three years, even in the great outdoors. Special powerful glue for residue-free design also makes the user doesn't need to clean the glue left on the object.

Matt Opaque Color Vinyl

Celadon Opaque Self-adhesive Calendaring Vinyl Film is a premium quality calendar film designed for use in signage markets where high quality film finish and cost-effective full color wrapping is required. The Celadon Easy Apply feature allows for faster positioning, special powerful glue for residue free design.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More