Cast PVC vs. Calendered PVC

Cast PVC

The term “cast” refers to the manufacturing process of cast PVC. Cast PVC is produced by first dissolving the PVC, plasticizer, and colorant using a solvent. Consequently, a thin film of the liquid mixture will then be poured onto a casting sheet. After that, it will be dried and cured in a series of ovens at a high temperature, producing a flexible film with a smooth finish. The casting sheet determines the texture of the surface of the film.

Because the temperature used during drying and curing processes is higher than that used in applications of the final product, cast PVC can withstand distortion, degeneration, warping, or degradation due to heat. It also has high dimensional stability since no pressure is applied during the production process. In addition, cast PVC is thinner, softer, and more flexible than calendered PVC, making them suitable for use in complex applications such as vehicle wrapping. Films produced by casting can last up to 12 years. However, casting is not suitable for large-scale production because of its high production cost; it also cannot produce wide-width films.

Calendered PVC

Matt Opaque Color Vinyl for Car Wrapping

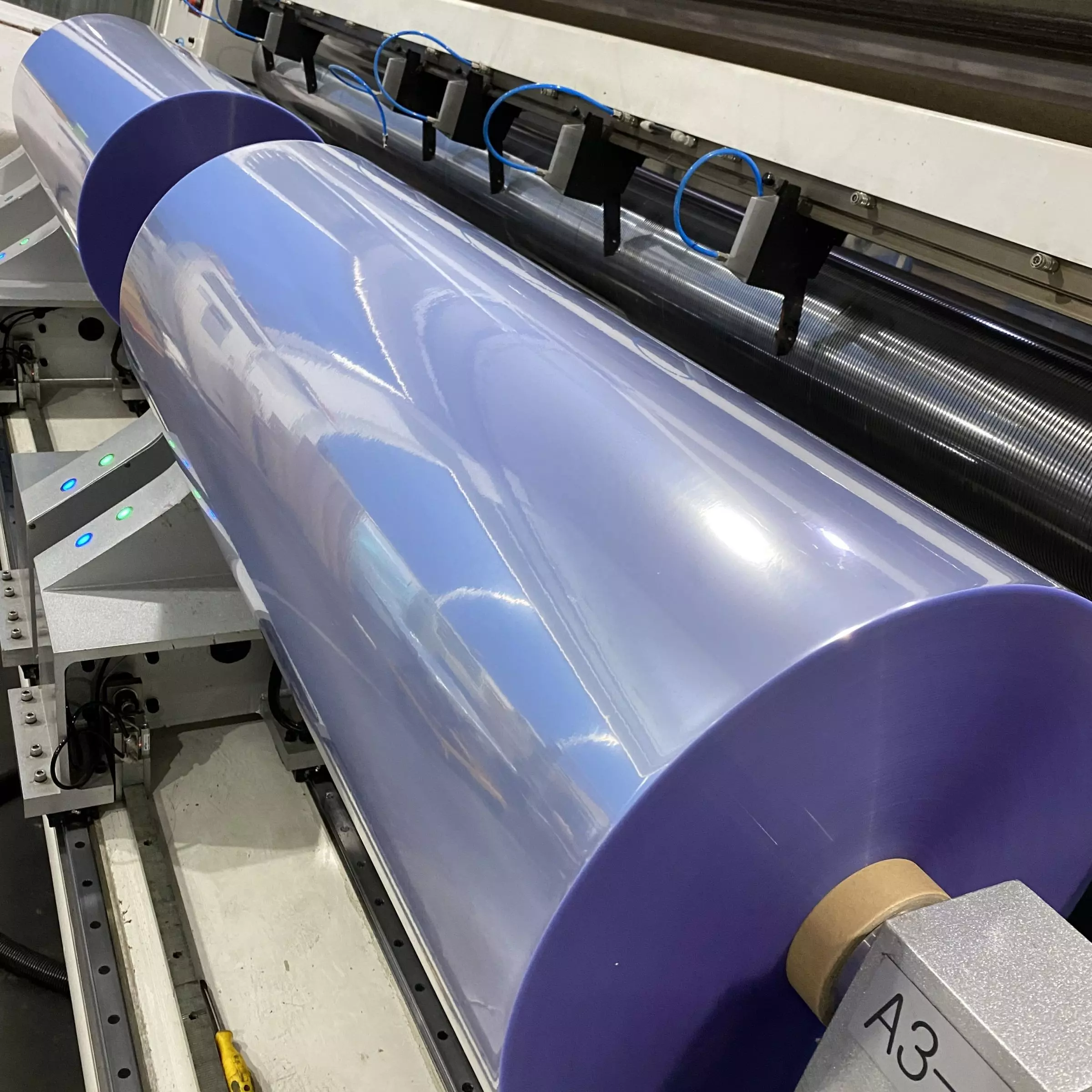

Calendered PVC is created by melting the PVC, plasticizer, and colorant altogether. The molten materials then are pressed by calendering rollers to achieve the desired width, thickness, and surface finish of the film. Calendered PVC is thinner and less resilient than cast PVC, but calendered PVC is suitable for many applications. It is usually used for short to medium-term applications that do not require conforming around complex surfaces such as point-of-purchase displays, window graphics, and partial wraps. The production cost of calendered PVC is lower than that of cast PVC because solvent and molds are not needed in manufacturing. Its service life usually lasts from two to seven years depending on the type of plasticizer used.

- Related Products

Matt Opaque Color Vinyl

Celadon Opaque Self-adhesive Calendaring Vinyl Film is a premium quality calendar film designed for use in signage markets where high quality film finish and cost-effective full color wrapping is required. The Celadon Easy Apply feature allows for faster positioning, special powerful glue for residue free design.

Glossy Opaque Color Vinyl

Celadon Opaque Self-adhesive Calendaring Vinyl Film is a premium quality calendar film designed for use in signage markets where high-quality film finish and cost-effective full-color wrapping is required. It has a glossy Opaque color outlook that allows every project goes smoothly when you use Celadon Opaque Vinyl. This amazing vinyl lies flat on your cutting machine, no tunneling or bubbling. Cut your design, weed with ease, and apply with awe. Even your most intricate designs effortlessly separate from the carrier sheet for a perfect application. Water-resistant and UV-resistant, lasts up to three years, even in the great outdoors. Special powerful glue for residue-free design also makes the user doesn't need to clean the glue left on the object.

Press Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More