FAQ

Q & A

Adhesive Strength Test

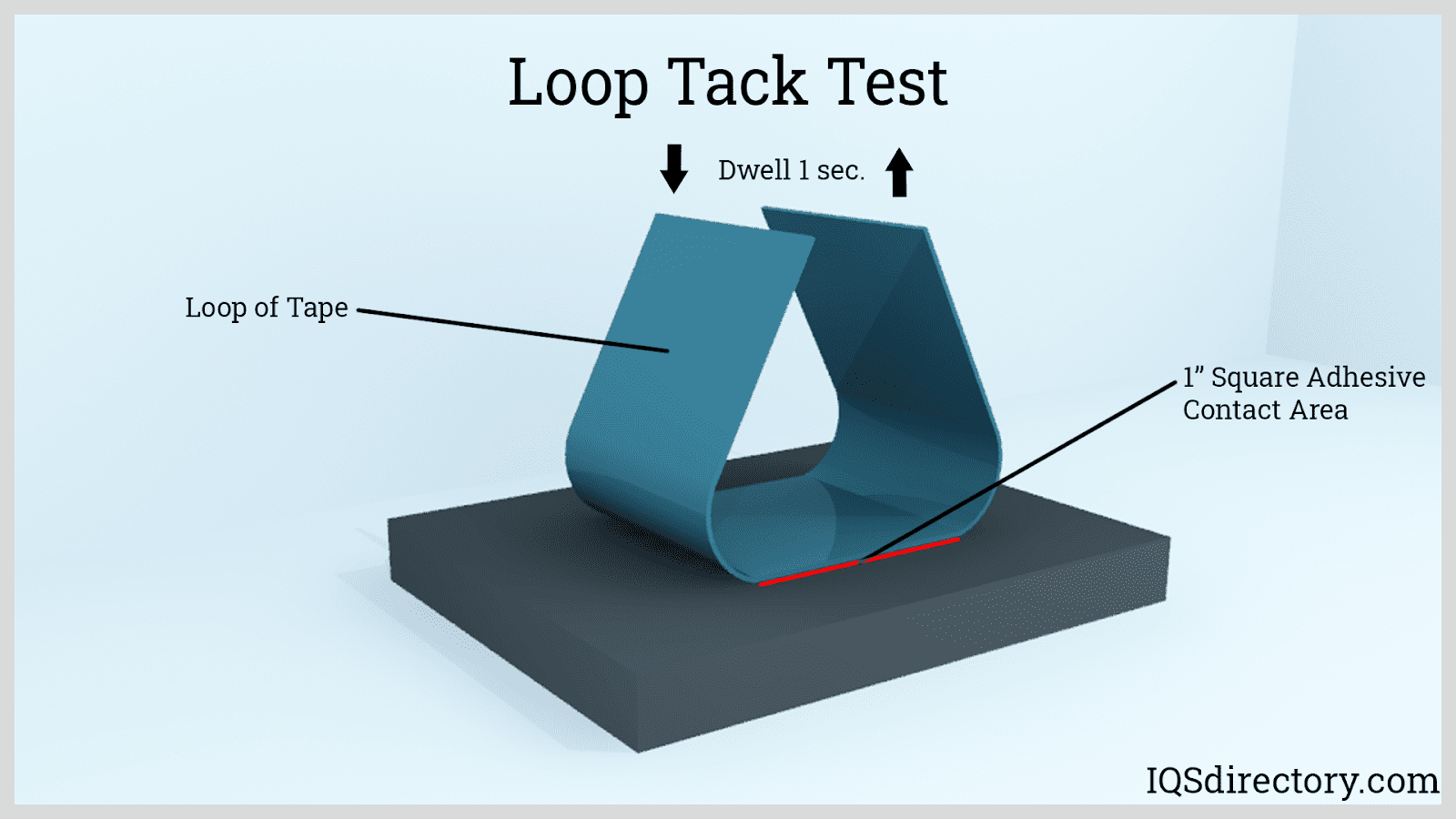

Loop Tack Test

Several methods are used to measure the tackiness of pressure sensitive adhesives attached to films, labels, stickers, and tapes. These include loop tests and 90º and 180º peel tests. In the loop test, a loop of adhesive tape attached to the probe of the testing machine makes contact with a horizontal surface and is pulled away after a short time. This measures the maximum force needed to peel off the tape from the substrate. In the 90º peel test, the adhesive tape is attached to a horizontal plate with the other end sticking up perpendicularly, forming an “L” shape. In the 180º peel test, the adhesive tape is placed vertically between the peel test grips with the free end of the tape gripped by the top forming a tight “U” shape. The 90º and 180º peel adhesion tests measure the constant force required to peel off the tape rather than the maximum force. The 90º peel adhesion test normally gives a lower value than the 180º peel adhesion test.

Celadon Technology Company Ltd. specializes in the production of premium vinyl graphic products and adhesive systems used in commercial and industrial applications. We implement stringent quality control procedures to ensure our products are of the best quality. We also have a dedicated research and development team to provide custom solutions to our client’s needs. Visit our website to learn more about us.

Read MoreCast PVC

The term “cast” refers to the manufacturing process of cast PVC. Cast PVC is produced by first dissolving the PVC, plasticizer, and colorant using a solvent. Consequently, a thin film of the liquid mixture will then be poured onto a casting sheet. After that, it will be dried and cured in a series of ovens at a high temperature, producing a flexible film with a smooth finish. The casting sheet determines the texture of the surface of the film.

Because the temperature used during drying and curing processes is higher than that used in applications of the final product, cast PVC can withstand distortion, degeneration, warping, or degradation due to heat. It also has high dimensional stability since no pressure is applied during the production process. In addition, cast PVC is thinner, softer, and more flexible than calendered PVC, making them suitable for use in complex applications such as vehicle wrapping. Films produced by casting can last up to 12 years. However, casting is not suitable for large-scale production because of its high production cost; it also cannot produce wide-width films.

Calendered PVC

Matt Opaque Color Vinyl for Car Wrapping

Calendered PVC is created by melting the PVC, plasticizer, and colorant altogether. The molten materials then are pressed by calendering rollers to achieve the desired width, thickness, and surface finish of the film. Calendered PVC is thinner and less resilient than cast PVC, but calendered PVC is suitable for many applications. It is usually used for short to medium-term applications that do not require conforming around complex surfaces such as point-of-purchase displays, window graphics, and partial wraps. The production cost of calendered PVC is lower than that of cast PVC because solvent and molds are not needed in manufacturing. Its service life usually lasts from two to seven years depending on the type of plasticizer used.

Read MoreMonomers are molecules that contain only carbon and hydrogen atoms. Polymers are made up of many monomers linked together. Calendering is a process where polymer films are stretched and heated to make them thinner and stronger. The most common types of calendered films are monomeric and polymeric. Monomeric films are usually used for packaging applications because they are strong and flexible. Polymeric films are often used for printing on paper products.

The Calendering Process

In order to create a calendered film, we first need to melt PVC resin, plasticizers and colorants together. Once melted, we pass the PVC through a series of rollers which flatten out the material and smooth out any imperfections. After passing through the rollers, the PVC is winded onto a spool.

About Plasticizer

The most common type of plasticizer used in vinyl flooring is phthalate esters. Phthalates are chemicals that soften plastics so they can be molded easily. Vinyl flooring contains a lot of phthalates because they make the vinyl flexible enough to mold. But these chemicals aren’t good for people. They can cause health issues like reproductive problems, hormone disruption, and cancer. That’s why we use only high quality REACH certificated plasticizers that don’t contain any harmful chemicals.

What do Monomeric and Polymeric mean?

Mono- and polymers are both chemical compounds that consist of long chains of atoms. The difference between mono- and polymers is how these chains are connected together. In monomers, each chain is attached to only one other chain. This makes monomers very small molecules. In polymers, on the other hand, there are multiple connections between chains. These connections make polymers much larger than monomers.

Polymeric Films

Polymeric films are made of long-chain plasticizers. Longer chain molecules bond together much better than short ones, so polymers are much stronger than monomers. They also have a higher glass transition temperature, which makes them more resistant to heat and cold. Polymer films are typically thicker than monomeric films, ranging from 100–400 microns. This allows them to withstand harsh environments like snow, rain, wind, and salt spray. Polymers also have a longer-lasting outdoor durability than monomers.

Polymeric PVC film has a better outdoor durability

Monomeric Films

Monomeric films are made of short-chain plasticizers. These short chains do not bind into the film very well. Overall, the short-chain plasticizers tend to migrate out of the film, making it brittle. In addition, monomeric film varies in thickness. It can be between 80 400 micron thick and has a tendency to shrink. especially the softer and flexible film. Therefore, these films are best for indoor flat applications and have a 3 – 5 year outdoor durability. Lastly, monomeric films have short-term outdoor durability that varies by manufacturer, making them more economical.

Monomeric PVC film is suitable for indoor or short-term outdoor application

Polymeric Film | Monomeric Films |

|

|

Read More

Parts of the Bond

The bonding layer made by an adhesive tape, shown macroscopically in the image below, presents a cross-section of a bond. The layer consists of an adhesion zone, cohesion zone, and a transition layer.

The adhesion zone is the interfacial layer between the adhesive and the substrate. The cohesion zone is the pure adhesive layer that holds the adhesive and the backing material, or another substrate if the adhesive is unsupported. The transition layer is intermediate between the adhesion and cohesion zones.

Mechanism of Action

The mechanism of adhesive tape bonding occurs as follows. These steps can be accomplished instantly after the activation of the pressure-sensitive adhesive.

- The pressure-sensitive adhesive on the tape is made to contact with the substrate by minimal pressure.

- Adhesive increases its surface area and penetrates through the surface of the substrate.

- Adhesive sets on the substrate, producing a strong bond.

The three elements of a pressure-sensitive adhesive tape to achieve a successful bond are adhesion, cohesion, and tackiness.

- Adhesion: Adhesion refers to the ability of an adhesive to stick on the surface of the substrate through adhesive forces. Adhesive forces refer to the attraction of two different materials. When the substrate and the adhesive molecules come in close proximity, adhesion forces occur at the microscopic level through intermolecular forces (e.g., van der Waals forces, dispersion forces) between them.

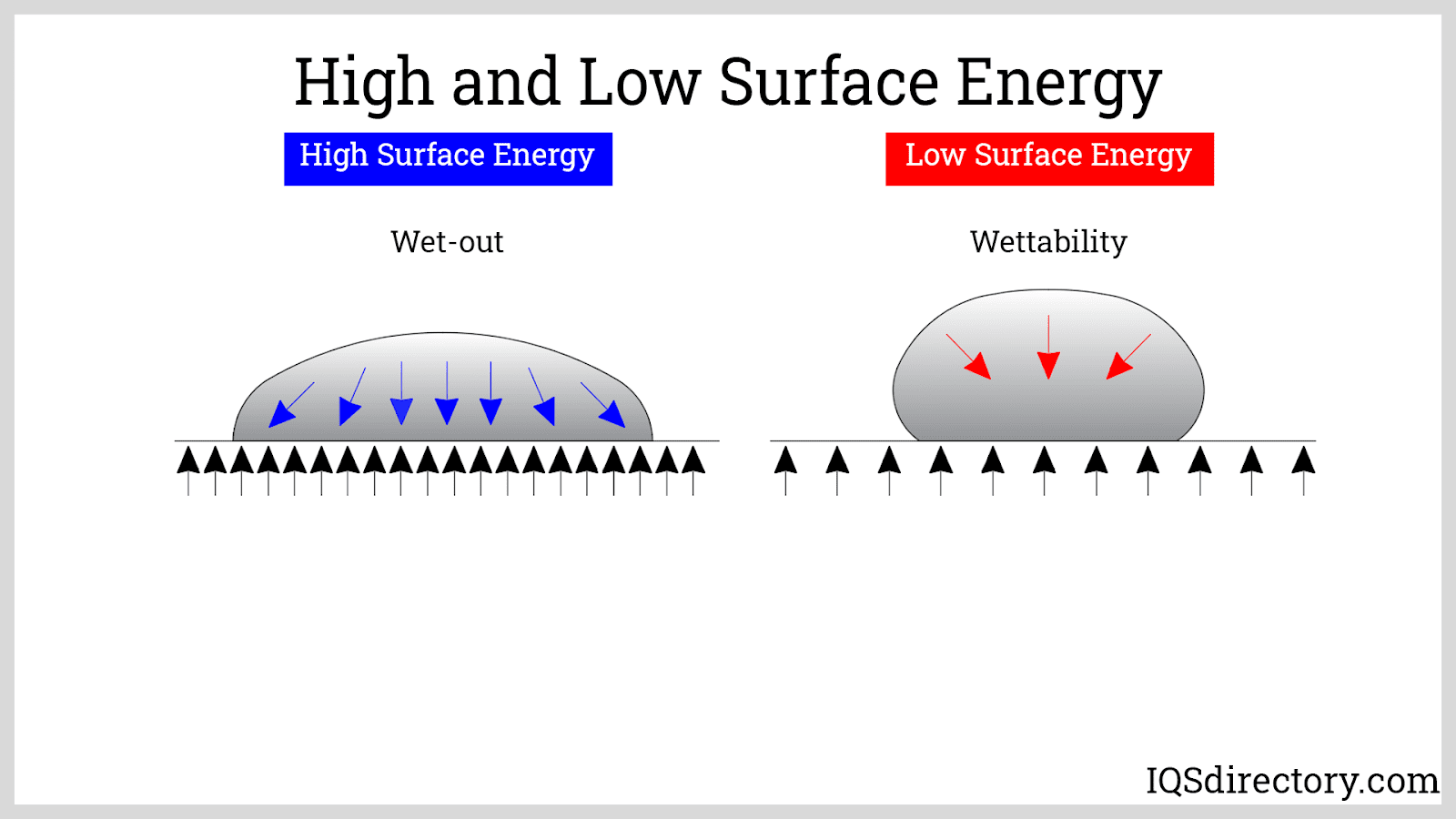

Surface energy is one of the properties which determines the wettability of the substrate when it comes in contact with the adhesive. Wettability is important to penetrate the surface of the substrate, thus making a continuous bond.

Surface energy is defined as the sum of the intermolecular forces, and the attraction and repulsion energies which a liquid exerts on the surface of a solid. If the substrate has high surface energy, the adhesive will easily flow on its surface and more surface area will be covered. Some of the high-energy substrates include polycarbonate, polyvinyl chloride, and zinc. On the other hand, if the substrate has low surface energy, the adhesive will build up as “small beads” and only a small area will be covered. Low surface energy substrates include Teflon, rubber, powder coatings, etc.

Surface contaminants prevent the fusion of the adhesive into the substrate. Therefore, it is important to keep the surface free from grease, dirt, and moisture before application of the adhesive tape.

- Cohesion: Cohesion is the inner strength of the adhesive. It refers to the bonding of the adhesive within itself. Cohesion holds the adhesive layer intact and prevents it from splitting.

Cohesive forces attract the neighboring molecules of a liquid by pulling it inward. Molecules at the surface of the liquid have greater attractive forces that bind them together. This phenomenon is responsible for the property of a liquid called surface tension. Surface tension is the ability of the adhesive to resist deformation on the surface of a solid, thus reducing its surface area. In the case of adhesive tapes, the molecules of the adhesive must be strong cohesive forces to hold and maintain the bond over time.

Silicone is an example of a liquid with high surface tension. If silicone is present as a coating on the surface of the substrate, it will be difficult to be wetted by the adhesive. If used as an adhesive, on the other hand, it will produce a durable bond.

Adhesion and cohesion must be considered when formulating or choosing the right adhesives. An ideal bond consists of a combination of a high surface energy substrate and a low surface tension adhesive. To achieve good wetting of the substrate, adhesive forces must be greater compared to cohesive forces and the contact angle must be less than 90°.

- Tackiness: Tackiness refers to the characteristic of a pressure-sensitive tape by which the adhesive sticks to the surface of the substrate under minimal pressure. All pressure-sensitive adhesives are activated by an initial finger pressure applied to the tape, usually from 14.5 to 29 psi. The required pressure and contact time for the adhesive tape to stick varies according to the type of adhesive and substrate material. Less pressure and contact time are required to stick for adhesive tapes with higher tack.

The phenomenon described is attributed to the viscoelasticity of the adhesive at room temperature. Viscoelastic objects are materials that possess both viscous and elastic characteristics. When gentle pressure is applied to the tape, it decreases its viscosity thus encouraging flow on the substrate at the microscopic level. Due to its elastic property, the original viscosity is regained with stronger intermolecular force with the substrate.

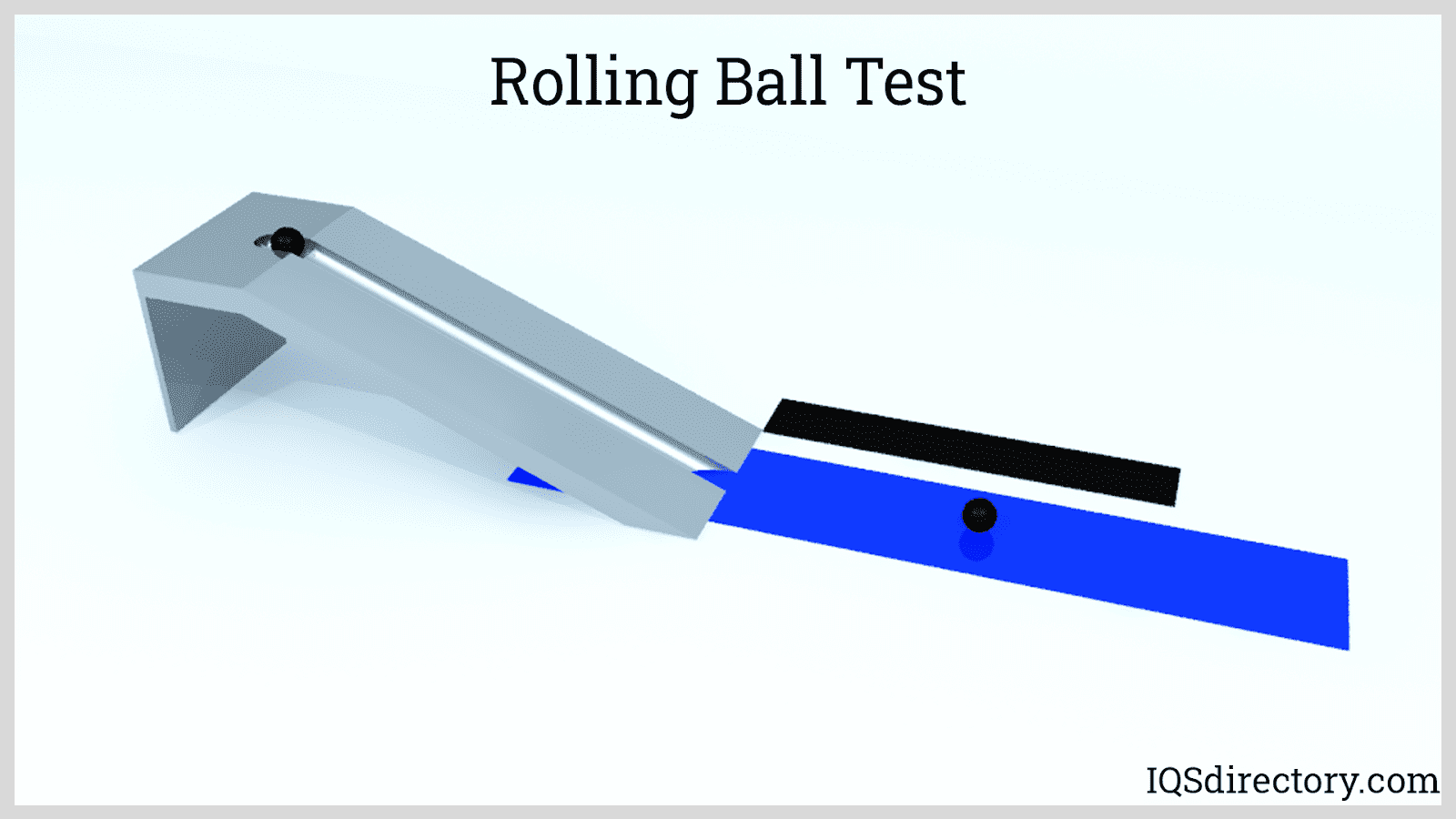

The Rolling Ball Test and Loop Tack Test are the most common quality control checks used to assess the tackiness of the adhesive tapes being produced.

- Rolling Ball Test: The rolling ball test directly gauges the adhesive behavior of the adhesive tape. A steel ball with a standard weight and diameter is made to roll from the top of an inclined track which consists of the sticky side of the tape. The tackiness is measured by the distance traveled by the ball on the sticky tape track; the shorter the distance, the greater the tack.

- Loop Tack Test: The loop tack test is a quantitative and repeatable method to assess adhesive tape tackiness. A loop of adhesive tape is attached to the probe of a tensile tester machine. The loop is made to contact with a horizontal surface for a short time, then the tool pulls it away. Numerical values of the bond’s tensile strength are recorded and subjected to evaluation.

Reference: https://www.iqsdirectory.com/articles/tape-suppliers/adhesive-tape.html?msID=1f7798fc-4305-49eb-8ba4-85ca244c575d#different-types-of-adhesive-tapes

Read MorePress Release

New PPF Developing

New PPF DevelopingCutting Age PPF is Under Development, TPU PPF's performance with reasonable price.

Read More